Why Use Peas Coal for Low-Pressure Boilers?

- National Coal Suppliers

- Aug 4, 2025

- 7 min read

Updated: Aug 7, 2025

Looking for cleaner, more efficient boiler fuel? Peas coal offers consistent burn rates, lower emissions, and reduced waste, ideal for low-pressure industrial steam systems.

About the Author: National Coal Supplier is a trusted source for 10,000+ monthly readers seeking industry insights on coal mining, gold, and chrome. Backed by industry analysts and technical writers, we provide accurate data on grades, specs, and sourcing of coal types, including peas, small nuts, and duff, serving buyers, exporters, and energy firms.

Key Takeaways:

Peas coal burns efficiently in low-pressure boilers with minimal ash.

Its uniform size ensures consistent heat transfer and lower fuel waste.

Ideal for small-scale industries seeking low-emission solid fuel.

Reduces operational costs by improving combustion and thermal control.

Convenient to source and store for various industrial applications.

Choosing the right fuel for your boiler isn't just a matter of cost, it's about performance, efficiency, and long-term reliability. For low-pressure steam systems, fuel consistency and combustion quality can make or break your operational efficiency.

Among the available solid fuel options, peas coal are a top choice for smaller, low-pressure industrial boilers. Its size, burn characteristics, and compatibility with automated systems make it an ideal fit for operations aiming for dependable, clean heat generation.

LOOKING FOR A RELIABLE COAL SUPPLIER? We supply and deliver high quality coal grade peas and small nuts to meet the needs of clients looking to increase their boiler efficiency. Contact us for pricing, specs, or bulk orders.

Why Peas Coal Suits Low-Pressure Boilers

Low-pressure boilers, commonly found in light manufacturing and food production, demand a fuel that offers fast response, manageable heat output, and minimal residue. Peas coal checks all these boxes thanks to its unique combustion characteristics.

Faster ignition and consistent steam ramp-up

One of the main advantages of peas coal is its ability to ignite quickly. This is especially beneficial in batch operations or facilities where frequent start-stop cycles are common. Rapid ignition helps bring boilers up to operational temperature faster, reducing downtime and improving energy efficiency during startup and shutdown periods.

Best coal size for low-pressure steam boilers

The particle size of peas coal allows it to spread evenly across combustion grates or within stoker-fed systems. This uniform distribution supports a stable firebed and eliminates dead zones where unburned fuel might accumulate. For boiler operators, this means less manual adjustment, fewer combustion issues, and more consistent steam generation throughout the production cycle.

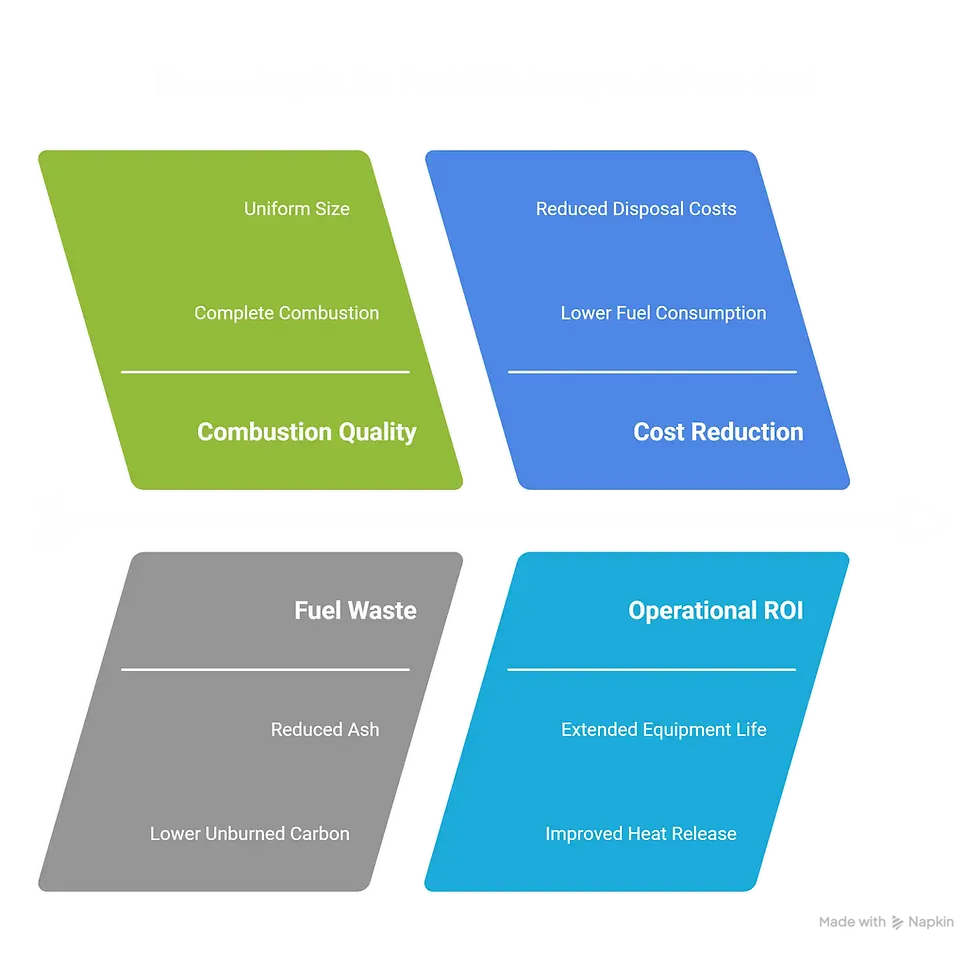

Fuel Efficiency & Cost Benefits

Boiler fuel efficiency isn't just about heat output, it's about maximizing the usable energy extracted from every ton of coal. Peas coal excels here, delivering better burn rates and minimizing waste across low-pressure systems. When used correctly, it can lead to noticeable reductions in fuel costs and improve operational ROI.

How peas coal improves boiler fuel efficiency

Peas coal improves efficiency by ensuring more complete combustion. Its fine, uniform size ensures that oxygen reaches all surfaces of the coal, leaving fewer unburned particles behind. This results in a higher heat release per kilogram of fuel used. Plants running on peas coal often report lower specific fuel consumption, particularly when compared to mixed or oversized coal grades.

Reduced unburned carbon and fuel waste

Because peas coal burns more completely, it produces less ash and retains less unburned carbon. This translates into lower disposal costs, cleaner combustion chambers, and less wasted fuel. Over time, these small gains can significantly reduce your operating costs and extend the service life of your equipment. Learn more about how to boost boiler efficiency with the right coal products.

Annual savings and consumption reduction examples

Facilities that transition to peas coal often see annual fuel consumption drop by 5% to 15%. For example, a textile plant that previously burned 1,000 tons of mixed coal annually switched to pure peas coal and cut usage by 120 tons. That saving, combined with reduced maintenance and ash disposal, added up to substantial annual cost reductions.

Maintenance & Emissions Advantages

Fuel selection doesn’t just affect combustion, it has downstream effects on maintenance schedules, system uptime, and environmental compliance. Peas coal contributes to cleaner, more reliable operation and helps meet growing demands for low-emission heat sources.

Low-emission solid fuel for small-scale boilers

Peas coal qualifies as a low-emission solid fuel for small-scale boilers. Its high carbon content and clean-burning profile minimize the production of particulate matter and sulfur dioxide. This makes it a practical solution for facilities needing to comply with emission limits or reduce environmental impact without investing in costly filtration or scrubbing technologies.

Less ash, soot, and clinker buildup

Combustion residues such as ash, soot, and clinker can affect boiler efficiency and increase maintenance frequency. Peas coal leaves behind a fine, manageable ash that’s easy to remove and unlikely to cause slag buildup. With less soot accumulation in heat exchangers, overall thermal transfer remains high, supporting better system performance over longer intervals. Learn more on how to calculate Coal consumption per ton of steam.

Compatibility: Boiler Types & Control Systems

Fuel performance is also influenced by the design of your boiler and the systems that control airflow and fuel feeding. Peas coal performs particularly well in low-pressure designs equipped with automated control features, but there are some compatibility considerations to be aware of.

Fire-tube vs. water-tube boilers

Peas coal is especially well-suited for fire-tube boilers, which dominate in low-pressure industrial settings. The stable flame and manageable heat output align well with fire-tube design parameters. In water-tube boilers, peas coal may also be used, but attention must be paid to feed systems and grate configuration to prevent bridging or incomplete burns.

Auto-feeding stokers and airflow settings

Modern boilers often use auto-feed stokers that regulate coal delivery into the combustion chamber. Peas coal flows smoothly through these systems, ensuring a consistent fuel supply. Its uniform size makes it responsive to precise airflow controls, helping operators achieve an optimal fuel burn rate with fewer manual interventions.

When mixing peas with other grades causes issues

Mixing peas coal with larger or smaller grades can lead to uneven combustion. Disparate sizes burn at different rates, which can result in cold spots, clinker formation, or unburned fuel. Consistency in fuel size is key to maintaining stable pressure and clean combustion. Understanding the difference between Peas and Small Nuts will allow you to make a informed decision on which product to choose.

How to Specify Peas Coal with Your Supplier

Purchasing high-quality peas coal involves more than asking for a size range. To get the best performance, you need to request data that confirms the coal's quality and suitability for your specific boiler system.

Ask for sieve analysis, calorific value, ash content

A trustworthy supplier should provide a detailed sieve analysis report, showing the percentage of coal within each size range. Also ask for calorific value (typically in MJ/kg), ash content, moisture level, and volatile matter. These values affect how well the coal burns and how cleanly it performs under real-world operating conditions.

Importance of consistent sizing and moisture control

Inconsistent sizing affects air-fuel mixing and combustion temperature. Excessive moisture reduces energy yield and increases flue gas volume. High-quality peas coal should maintain moisture below 12% and contain minimal fines or oversize pieces. National Coal Suppliers guarantees tightly screened and moisture-controlled batches for maximum performance. Learn more about the best coal for Lime production in South Africa.

Real-World Use Cases & Operational Tips

Peas coal is already in use across a wide range of industries where steam is required at consistent, manageable pressures. These use cases demonstrate its real-world value and provide insights into optimizing your own system.

Benefits of using peas coal in industrial boilers

Industries including textile manufacturing, food processing, and small chemical plants rely on peas coal to meet their steam demands efficiently. These facilities benefit from fewer boiler stoppages, more consistent product output, and reduced labor costs. For businesses operating under strict margins, peas coal delivers a valuable combination of cost savings and reliability.

Fuel feed rate, air intake, cleaning schedules

To get the most from peas coal, follow manufacturer guidelines for fuel feed rate and air intake. Monitor the flame color and shape for optimal combustion—a bright, consistent flame indicates efficient burning. Schedule cleaning at regular intervals to remove ash from grates and exchange surfaces. Following these practices helps maintain boiler efficiency and reduces long-term repair costs.

Fanial Thoughts

Peas coal for low-pressure boilers offers unmatched reliability, combustion efficiency, and environmental advantages. Its uniform size, fast ignition, and clean burn make it a smart choice for industrial operations looking to optimize performance without increasing maintenance or emissions. Whether you're upgrading fuel supply or looking to improve system uptime, peas coal delivers proven results.

Ready to upgrade your fuel supply? Contact National Coal Suppliers today to request a free sample, full technical specification, or a tailored supply quote. We’ll help you choose the right coal grade to keep your operations running smoothly and efficiently.

Frequently Asked Questions

What makes peas coal more consistent than other fuel grades?

Peas coal is mechanically screened to strict sizes. This uniform sizing ensures that combustion occurs evenly, reducing hot spots and fuel waste. Unlike mixed coal loads that contain varying sizes and dust, peas coal supports predictable combustion patterns. This consistency is especially important in automated feeding systems, where irregular particle sizes can clog hoppers or cause unstable burn rates. Industrial users prefer peas coal because it allows for more precise system tuning and fewer manual adjustments.

Can peas coal be used in dual-fuel boiler systems?

Yes, peas coal can be used in some dual-fuel systems, provided the equipment is designed to accommodate solid fuel alongside oil or gas. These systems must include dedicated feed mechanisms and combustion chambers optimized for solid fuel combustion. Peas coal’s clean-burning nature makes it an attractive secondary fuel for backup or supplementary heating. However, consult your boiler manufacturer or supplier to verify compatibility and avoid combustion control issues when switching between fuels.

How does peas coal impact flue gas composition?

Peas coal produces cleaner flue gases than many other grades due to its higher fixed carbon content and lower volatile matter. This results in reduced particulate matter, less sulfur dioxide (SO2), and minimal visible smoke. Cleaner flue gases improve heat exchange efficiency and reduce the strain on emission control equipment. For facilities with air quality monitoring requirements, peas coal helps achieve compliance while minimizing filtration and scrubbing costs.

Is peas coal suitable for off-grid or rural industrial operations?

Absolutely. Peas coal is well-suited for off-grid or remote industrial sites where reliable electricity and fuel supply may be limited. Its consistent performance, ease of storage, and ability to be fed through simple gravity-fed stokers make it ideal for standalone boiler operations. It provides an affordable, high-efficiency heating option without requiring advanced digital control systems. This makes peas coal a practical fuel choice for mines, farms, and rural production facilities.

What storage conditions are ideal for preserving peas coal quality?

To preserve its quality, peas coal should be stored in a dry, covered area protected from rain and ground moisture. Proper storage prevents clumping, reduces moisture absorption, and ensures the coal maintains its energy density. Use raised platforms, lined bins, or tarpaulins to prevent contamination with dust or soil. Consistent moisture levels also support predictable combustion and make it easier to meet performance expectations in your low-pressure boiler system.