How to Improve Boiler Efficiency With the Right Coal Size

- National Coal Suppliers

- Jul 25, 2025

- 6 min read

Updated: Aug 21, 2025

Choosing the correct coal size, such as coal peas or small nuts, can significantly improve industrial boiler efficiency, reduce waste, and lower operational costs over time.

About the Author: National Coal Supplier is a trusted source for 10,000+ monthly readers seeking industry insights on coal mining, gold, and chrome. Backed by industry analysts and technical writers, we provide accurate data on grades, specs, and sourcing of coal types, including peas, small nuts, and duff, serving buyers, exporters, and energy firms.

Key Takeaways

Coal size directly affects combustion efficiency in boilers.

Coal peas often offer better performance in power plants.

Small nuts are suited for specific industrial applications.

Matching coal type to boiler design reduces fuel consumption.

Proper coal selection lowers emissions and boosts cost savings.

Boiler efficiency hinges on fuel quality, and when it comes to coal, size matters. Many industrial operations struggle with inconsistent steam pressure, excessive ash, or unplanned downtime, only to find that the wrong coal type is to blame. Choosing between coal peas and small nuts isn’t just about what's available. It’s about what performs best in your system.

In this guide, we’ll break down the combustion characteristics, efficiency advantages, and use-case differences between coal peas and coal small nuts. We’ll explain which works best in industrial boilers, why sizing impacts combustion, and how you can optimize both performance and cost.

LOOKING FOR A RELIABLE COAL SUPPLY PARTNER? We source and deliver high quality coal grades including peas, small nuts, duff, and RB1 to meet the needs of local and export buyers. Contact us for pricing, specs, or bulk orders.

What’s the Difference Between Coal Peas and Small Nuts?

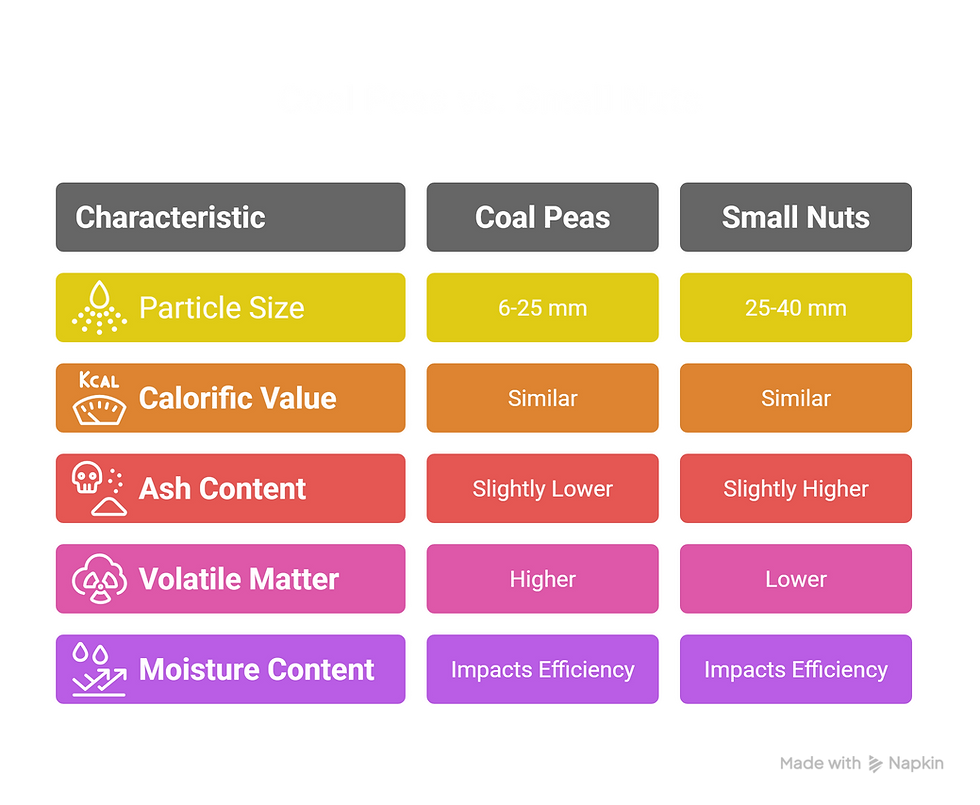

Coal peas and small nuts are graded by particle size, with coal peas typically ranging from 6 to 25 mm and small nuts falling between 25 and 50 mm. The smaller size of peas means a higher surface area-to-volume ratio, which allows for faster ignition and combustion. Small nuts, with their larger mass, burn slower and more consistently.

Key characteristics to compare:

Calorific value: Often similar by grade but affected by sizing

Ash content: Slightly higher in small nuts depending on source

Volatile matter: Crucial for ignition efficiency; higher in some coal peas

Moisture content: Impacts storage, ignition, and thermal efficiency

Understanding these traits is essential when deciding which coal type to use in your boiler system. Making the wrong choice can affect combustion quality, heat output, and maintenance frequency.

How Do Coal Sizes Affect Boiler Performance?

Most industrial boilers fall into two categories: fire-tube and water-tube. Fire-tube boilers, common in smaller facilities, perform well with consistent, moderate combustion. Water-tube systems, used in power plants and heavy industry, demand hotter, faster-burning fuels.

In our work with textile and food processing plants, we’ve seen that mismatching coal size to boiler type leads to either underperformance or waste. For example:

Coal peas: Ideal for quick, high-heat demand cycles

Small nuts: Better for long, steady combustion processes

Typical operating conditions:

Steam pressures: 10-30 bar

Temperatures: 180-300°C

Selecting the right coal size ensures the boiler operates within optimal parameters. This results in improved thermal transfer and a more consistent steam supply. Learn more about steam boiler maintenance tips for coal-fired systems.

Why Choose Coal Peas for Power Plants?

Coal peas are ideal for systems where fast ignition and high flame intensity are needed. They offer superior combustion control when paired with automated stoking systems. We’ve found that companies using coal peas in power plants or high-pressure steam boilers often report:

Reduced start-up time

More complete fuel burn

Lower unburned carbon in ash

Coal peas also support better flame stability, especially under fluctuating load conditions. These benefits directly enhance boiler efficiency and fuel economy.

When Are Small Nuts a Better Option?

Coal small nuts are favored in applications requiring stable heat over longer durations. Industries like cement, agriculture drying, and heavy manufacturing often rely on their slower burn rate.

Industrial uses include:

Rotary kilns and batch drying systems

Steam-driven refrigeration in food plants

Large commercial heating systems

Their size allows for more controlled combustion in systems without automated feed regulation. If you're operating in conditions that require consistent thermal output, small nuts are a dependable option.

The keyword coal peas small nuts combustion efficiency highlights a critical point: burn rate control. Peas ignite faster, reach combustion temperature quicker, and produce less residual ash when used correctly. Small nuts, on the other hand, offer consistent output when stoking frequency is limited.

Best practices:

Match air supply to fuel type.

Monitor ash buildup patterns.

Adjust feed rate based on burn-back.

Choosing the right size improves combustion completeness and lowers flue gas emissions. Efficient combustion also reduces fuel consumption and extends equipment life.

Storage, Handling, and Operation Tips

To maintain combustion quality and boiler efficiency:

Keep coal dry: Moisture reduces calorific value and increases emissions.

Use proper stoking techniques: Ensure even bed depth and feed rate.

Avoid size mixing: Inconsistent combustion and ash clogging often result.

Poor storage conditions can compromise combustion, causing issues like high unburned carbon. Sticking to best practices ensures reliable output and smoother operations.

Cost and Supply Chain Considerations

While coal peas may cost slightly more per ton, they often produce more usable heat per kilogram. In contrast, small nuts are often easier to source regionally.

Key tips:

Verify specs before buying: Particle size, calorific value, moisture content

Negotiate based on delivered energy (GJ/ton), not just weight.

Check supplier compliance with SANS or ISO coal grading standards.

Supply consistency and delivery timing are just as important as cost. Work with vetted suppliers that offer quality control and documentation.

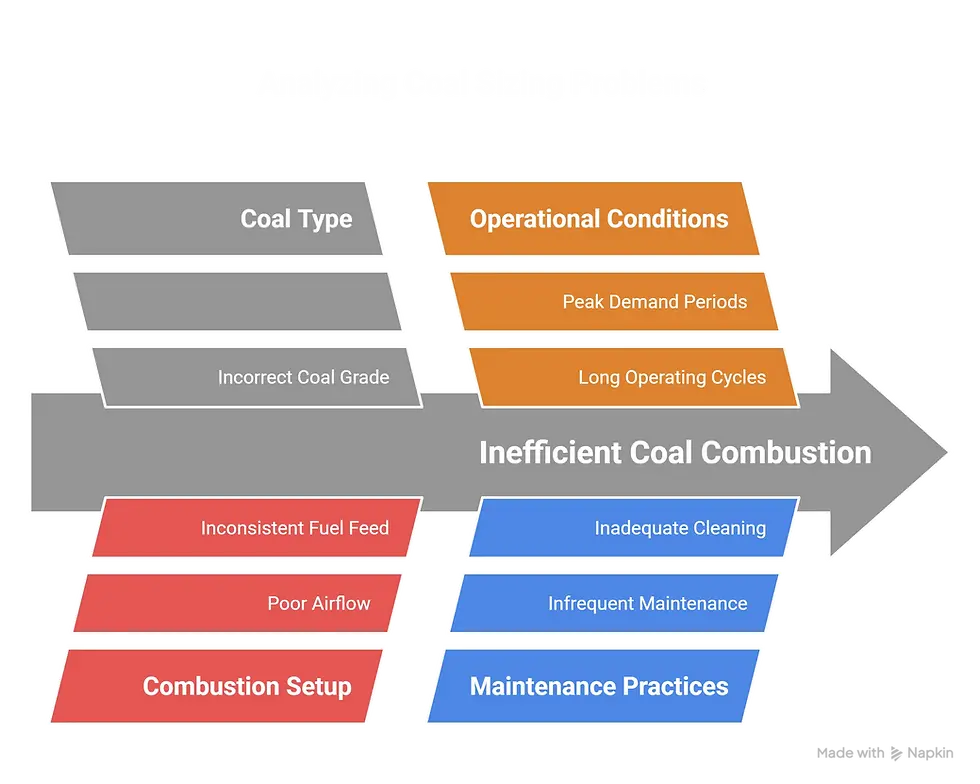

Common Problems With Incorrect Coal Sizing

Choosing the wrong coal type can lead to:

Clinker formation: Hard ash deposits on the grate

Uneven steam pressure: Caused by inconsistent combustion

Higher maintenance costs: ash fouling, emission spikes, feed system damage

These issues often surface during periods of peak demand or long operating cycles. Adjusting fuel type or combustion setup can resolve most of these quickly.

Environmental and Safety Considerations

Coal combustion releases particulate matter and SOx/NOx. While these emissions vary by coal grade, proper sizing improves combustion efficiency and reduces output.

Tips:

Use emission scrubbers or cyclones.

Train staff on safe storage and handling.

Comply with local emissions caps and occupational health rules.

Smarter combustion reduces environmental impact and lowers your regulatory risk. Proper training also improves on-site safety and operational consistency.

Frequently Asked Questions

Can you switch between coal peas and small nuts in the same boiler?

Yes, but only if the boiler is configured to handle varying combustion rates. Switching requires adjusting air intake, stoking frequency, and possibly grate setup. In some systems, mixed use causes uneven combustion, pressure drops, or excessive ash. Always test and monitor output when switching sizes. Review operating parameters and consult with a combustion specialist to minimize performance loss or damage.

How does coal size impact boiler cleaning frequency?

Smaller coal like peas tends to burn cleaner with less unburned carbon, reducing ash accumulation. However, if moisture content is high, it can still cause slag. Larger coal like small nuts often leads to more clinker and buildup, increasing the need for soot blowing or manual cleaning. Burn tests help set optimal cleaning intervals. The right size can lower downtime and reduce labor costs over time.

What’s the ideal coal size for low-pressure boilers?

Coal peas typically perform better in low-pressure boilers due to their quick ignition and high surface area. They help maintain consistent steam generation without overheating the chamber. Small nuts may work but often result in slower ramp-up or inconsistent burn unless carefully managed. Check OEM fuel size recommendations. Fuel testing is a reliable way to validate compatibility with your setup.

Are there emissions differences between coal peas and small nuts?

Yes. While the coal grade impacts emissions more than size, burn efficiency plays a big role. Coal peas often burn more completely, which can reduce CO and unburned particulates. Poor combustion of small nuts leads to visible smoke and higher PM levels. Use an emissions analyzer to verify compliance. Regular tuning and airflow management also improve performance.

Do coal suppliers guarantee sizing accuracy?

Some do, but not all. Always request a detailed spec sheet, including screen size used, calorific value, and moisture levels. If possible, ask for a sieve analysis. Confirm batch consistency across deliveries, especially when using automated stoking systems where sizing errors cause jams or uneven feed. Partnering with reliable suppliers reduces risk and supports quality assurance.

Right Coal Size, Better Efficiency, Lower Costs

Choosing the right coal size, whether peas or small nuts, can dramatically improve boiler performance. From fuel savings to better combustion and fewer maintenance issues, proper sizing leads to measurable gains. Always match fuel characteristics to boiler requirements and monitor regularly. This simple step can enhance your plant’s reliability and reduce operating costs.

For tailored advice and reliable coal sourcing, contact us today. Request samples or download our comprehensive guide to optimize your coal fuel strategy.