What Are the Effects of Poor-Quality Coal in Boilers?

- National Coal Suppliers

- Jul 30, 2025

- 8 min read

Updated: Aug 21, 2025

Coal quality directly affects boiler efficiency, emissions, and maintenance costs. Learn how to identify poor fuel, troubleshoot performance issues, and choose the right coal for your plant.

About the Author: National Coal Supplier is a trusted source for 10,000+ monthly readers seeking industry insights on coal mining, gold, and chrome. Backed by industry analysts and technical writers, we provide accurate data on grades, specs, and sourcing of coal types, including peas, small nuts, and duff, serving buyers, exporters, and energy firms.

Key Takeaways:

Poor coal leads to slagging, fouling, and unstable combustion.

Ash, moisture, and sulfur levels drive operational issues.

Proximate and ultimate analysis detect fuel problems.

Consistent sizing and washing reduce slag and downtime.

Long-term savings come from reliable, quality fuel sourcing.

Industrial boilers rely heavily on fuel quality to perform efficiently and safely. When the coal being used doesn’t meet required standards, it can trigger a chain of performance and maintenance issues that reduce output, raise operating costs, and cause unexpected downtime. Across South Africa’s energy, manufacturing, and mining sectors, coal quality issues in industrial boilers are a frequent cause of frustration for maintenance teams and plant managers alike.

In this article, we’ll explore what coal quality means, the specific problems that poor coal can create, how to diagnose them, and how to fix them before they impact productivity. If you operate or oversee coal-fired boilers, this guide will help you troubleshoot recurring problems and make smarter sourcing decisions going forward.

LOOKING FOR A RELIABLE COAL SUPPLIER? We supply and deliver high quality coal grade peas and small nuts to meet the needs of clients looking to increase their boiler efficiency. Contact us for pricing, specs, or bulk orders.

What Is Meant by Coal Quality in Industry?

Coal quality refers to the physical and chemical characteristics of coal that influence its combustion behavior, heat output, and impact on boiler operations. In industrial settings, quality is not just about how much heat coal can produce; it's also about how cleanly and consistently it burns.

Key Metrics: Calorific Value, Moisture, Ash Content

These are the primary indicators of coal performance:

Calorific Value (CV): The amount of energy released when coal is burned. Low CV coal produces less heat per ton, which reduces overall boiler efficiency.

Moisture Content: High moisture reduces combustion temperature and increases unburnt carbon losses.

Ash Content: Ash is the non-combustible residue. High ash levels cause slagging, fouling, and frequent cleaning cycles.

Other important factors include sulfur content, volatile matter, grindability, and particle size distribution. Learn more about how to boost boiler efficiency with the right coal products.

Which Coal Size Works Best in Industrial Boilers?

When boiler performance depends on consistent fuel quality, the size and type of coal you use makes a real difference. Poor sizing can cause clinkers, flame instability, or incomplete combustion, problems that cost time and money to fix. That’s why coal peas and coal nuts are preferred for industrial use.

Coal peas (6–25mm) and small nuts (25–50mm) offer the best balance of surface area and airflow. Their size supports steady combustion, smooth feeder flow, and predictable ash behavior. With fewer blockages, more complete burn, and easier handling, these products help eliminate coal quality issues from the start.

Plants that switch to properly screened coal peas or nuts often report better boiler response, lower slag buildup, and fewer disruptions over time. Understanding the difference between Peas and Small Nuts will allow you to make a informed decision on which product to choose.

Why Grading and Consistency Matter in Boilers

Boilers are designed with specific coal grades in mind. Even slight variations in size or ash content can cause burner instability, excessive clinker formation, or underperformance. Unpredictable coal quality forces operators to constantly adjust air-fuel ratios and may lead to equipment stress over time.

Common Coal Quality Issues in Industrial Boilers

Using the wrong coal or coal with inconsistent properties, can lead to several performance and maintenance challenges. These are the most common issues operators face.

High Ash Content and Clinker Formation

Excessive ash doesn’t just reduce thermal efficiency, it leads to clinker formation, which is when molten ash fuses into hard deposits on boiler surfaces. This causes slagging, restricts airflow, and increases the risk of shutdowns.

Low Calorific Value and Heat Rate Loss

Low-grade coal in boilers often produces less energy per ton, requiring more fuel to reach target steam output. This results in calorific value loss, higher operating costs, and emissions penalties.

Wet or Unwashed Coal Causing Combustion Delays

Coal with excessive surface moisture causes flame instability and combustion temperature issues, making it harder to maintain steady pressure or temperature output. Wet fuel also increases drying time inside the boiler, reducing throughput.

Oversized or Inconsistent Coal Particle Size

Coal that’s not uniformly sized leads to poor combustion. Larger chunks may burn unevenly, while fines may pass through the system unburnt. The result is flame instability and fuel-air mix troubleshooting that affects burner tuning and emissions control. Learn more about the best coal for Lime production in South Africa.

What Are the Signs Your Boiler Is Affected by Poor Coal?

Coal problems often creep in slowly. At first, operations seem normal, but over time, performance dips, maintenance costs rise, and inconsistencies appear across systems. Watch for these red flags:

Fluctuating steam pressure and unstable loads: Poor-quality coal causes uneven combustion, which throws off steam generation and destabilizes the system. This puts stress on feedwater pumps, valves, and control loops.

Ash fouling, slagging, and soot buildup: Excess ash and soot coat boiler tubes, restricting airflow and reducing heat transfer. You’ll likely see more shutdowns for cleaning or unexpected drops in thermal efficiency.

Increased coal use with no output improvement: If you’re burning more fuel but seeing the same output, poor coal is likely wasting energy and dragging down your plant’s efficiency.

Even one of these signs can point to bigger fuel quality issues. Addressing them early reduces operational strain and protects your boiler from long-term damage. Learn more on how to calculate Coal consumption per ton of steam.

What Are Early Warning Signs of Coal Problems?

Coal quality issues often start small but snowball into major inefficiencies if ignored. Operations may seem stable at first, until your systems start showing signs of stress.

Look out for these red flags:

Steam pressure that won’t stay consistent: Unstable combustion from poor-quality coal causes fluctuating steam loads, which puts strain on feedwater pumps, valves, and automated controls.

Frequent ash fouling and slag formation: High ash content leads to soot buildup on boiler tubes, lowering heat transfer and triggering more shutdowns for cleaning or derating.

Fuel usage keeps rising without more output: If your coal burn rate increases but your plant output doesn’t, chances are you’re losing energy to low-calorific or inconsistent fuel.

Even one of these issues could mean your coal isn't meeting spec. Spotting the signs early helps avoid equipment wear, unstable output, and unnecessary costs.

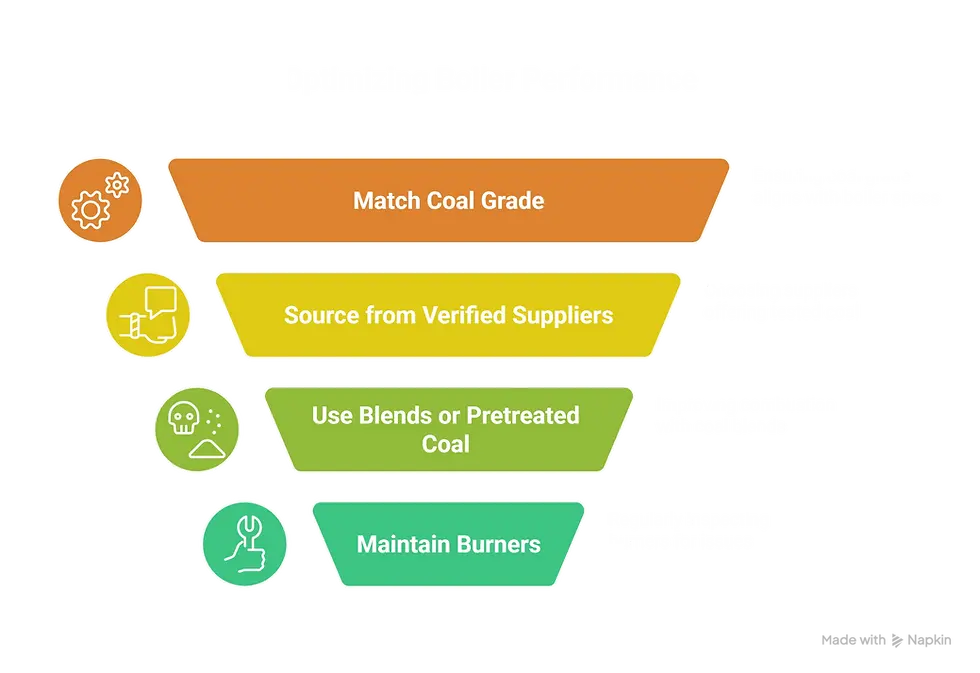

How to Fix Coal Quality Issues in Your Boiler

Coal-related problems often come down to inconsistency, poor sourcing, or mismatched fuel grades. Once you know what your boiler is built to handle, you can take clear steps to fix the problem and prevent it from recurring:

Match Coal Grade to Boiler Specs: Check your boiler manufacturer’s specifications and make sure your coal grade aligns. Using the wrong grade reduces combustion efficiency and accelerates wear.

Buy from Verified South African Suppliers: Only source from suppliers who offer washed, graded, and tested coal. National Coal Suppliers, for example, delivers fuel tailored to industrial boiler standards with full traceability.

Use Blends or Pretreated Coal: If high-grade coal is inconsistent, blending it with lower-grade fuel can improve combustion and reduce slag. Suppliers often offer tested blends based on your boiler profile.

Maintain and Monitor Burners Routinely: Even high-quality coal won’t perform well with neglected burners. Inspect burners regularly for slag buildup, flame instability, and wear to avoid unplanned outages.

Taking these steps ensures your boiler runs within spec, lowers operating costs, and minimizes coal-related downtime.

How Does Consistent Fuel Quality Reduce Operating Costs?

Using higher-quality coal might raise upfront costs, but the long-term operational savings often outweigh the price difference. Here's how consistent fuel quality leads to lower overall expenses:

Fewer shutdowns and boiler maintenance events due to reduced fouling, slagging, and wear on tubes and boiler components

Improved combustion and energy efficiency because uniform coal burns more completely with less excess air

Lower cleaning and inspection costs from less soot buildup and fewer unplanned interventions

Better supplier accountability with defined specs, quality controls, and fewer disputes over variable fuel batches

Stronger contract leverage through long-term relationships that prioritize consistent supply and reliable delivery

By locking in consistent coal quality, plants reduce variability, optimize performance, and ultimately lower the cost per ton of steam produced.

Take Control of Your Fuel Supply Today

Coal quality shouldn’t be an afterthought, t’s a critical driver of boiler performance, operating costs, and long-term asset reliability. If you’re seeing recurring issues with slagging, inconsistent pressure, or rising fuel use, it’s time to re-evaluate your supply chain.

National Coal Suppliers works with industrial clients across South Africa to deliver tested, graded, and performance-matched coal solutions. Get in touch today to discuss your specific boiler requirements, schedule a coal sample test, or set up a supply assessment.

Frequently Asked Questions

What are the signs of bad coal in boilers?

Common signs of poor-quality coal include sudden pressure drops, inconsistent steam output, higher fuel consumption, and unstable or smoky flames. You might also notice slagging and fouling on heat exchange surfaces, which reduce efficiency. Ash deposits and clinker buildup can damage boiler components. Conducting visual ash inspections, reviewing burner logs, and comparing recent combustion data can help isolate whether the coal is causing operational issues. Consistency in feedstock quality is critical for smooth boiler performance.

How does ash content affect boiler operations?

High ash coal significantly impacts efficiency by leaving behind more residue that accumulates inside the boiler. This buildup restricts heat transfer, requiring more frequent cleaning and increasing downtime. Ash can also lead to slagging on furnace walls and clinkers on the grate, both of which disrupt combustion and airflow. Over time, excessive ash shortens boiler lifespan and raises maintenance costs. Monitoring ash levels helps operators match coal quality to boiler design and minimize performance losses.

What tests determine coal quality for boilers?

Coal quality is typically assessed through proximate and ultimate analyses. Proximate analysis measures ash, moisture, volatile matter, and fixed carbon, key indicators of combustion behavior. Ultimate analysis goes deeper, evaluating elements like sulfur, nitrogen, hydrogen, and oxygen. Calorific value tests reveal energy output per unit of coal, while grindability affects how easily coal can be pulverized for efficient burning. These tests help operators determine fuel suitability and detect quality deviations before they affect boiler performance.

Which coal type is best for minimizing slag?

To minimize slag formation, choose coal with low ash content, low sulfur levels, and a high ash fusion temperature. These properties reduce the likelihood of ash softening and sticking to furnace surfaces. In South African industrial applications, washed coal with consistent size distribution is often used to maintain clean combustion. Stable blends reduce thermal stress and limit slag buildup on superheaters and boiler tubes. Proper coal selection is essential for efficient, low-maintenance operations in high-demand systems.

Can moisture in coal affect combustion rate?

Yes, high moisture content directly impacts combustion efficiency. Before coal can burn, its water content must first evaporate, which consumes additional energy and reduces flame temperature. This leads to slower combustion, incomplete burning, and higher emissions. Wet coal can also clog hoppers and reduce boiler responsiveness. For best results, use pre-dried or stored coal with low inherent moisture. Monitoring inbound coal moisture ensures consistent combustion rates and reduces thermal inefficiencies in industrial boilers.

How often should fuel quality be tested in plants?

Coal quality should be tested with every new delivery, especially in operations that rely on consistent combustion for production. Routine sampling helps identify impurities, moisture levels, ash content, and calorific value before the coal enters the system. Inconsistent quality can lead to inefficiencies, unplanned outages, and equipment damage. Plants running continuous or high-pressure operations benefit from standardized testing protocols to ensure the fuel matches boiler design specs and to avoid costly troubleshooting down the line.