Is Coal Still Viable for Medium-Sized Boiler Operations?

- National Coal Suppliers

- Jul 27, 2025

- 5 min read

Updated: Sep 1, 2025

About the Author: National Coal Suppliers is a trusted source for 10,000+ monthly readers seeking industry insights on coal mining, gold, and chrome. Backed by industry analysts and technical writers, we provide accurate data on grades, specs, and sourcing of coal types, including peas, small nuts, and duff, serving buyers, exporters, and energy firms.

Key Takeaways

Coal still powers most medium-capacity boilers in SA.

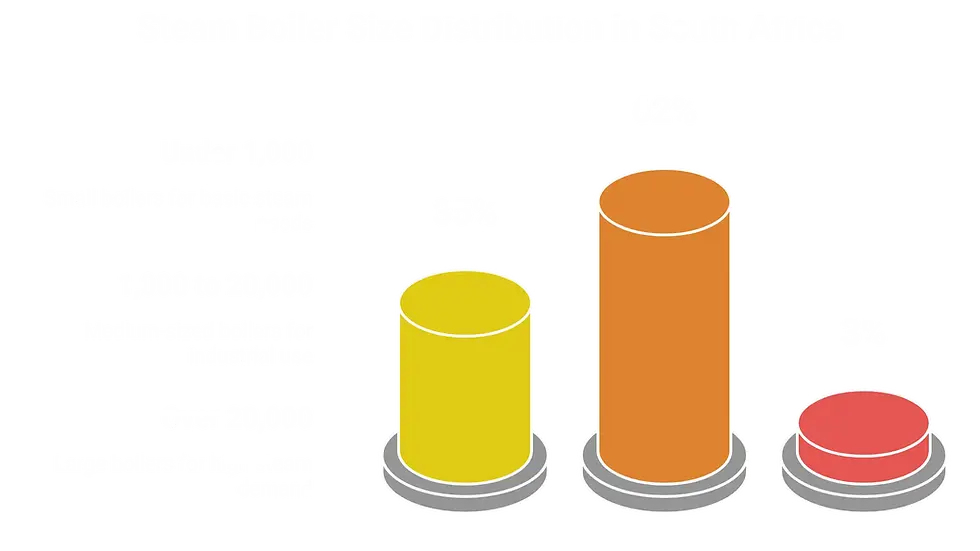

35% of boilers are under 1,000 kg/hr, and only 3% are above 20,000 kg/hr.

Emission compliance is tightening for coal-fired systems.

Cost, availability, and infrastructure still favor coal in some areas.

Businesses must weigh coal’s risks vs. benefits in 2025.

Coal-fired boilers have long powered medium-sized industrial operations across South Africa. As environmental policies tighten and energy costs shift, many facility managers are reassessing their fuel strategies.

While alternative fuels like gas, biomass, and electricity are gaining traction, coal remains a dominant energy source in many regions, especially where infrastructure and supply chains are already in place.

Understanding coal’s current viability means weighing cost, availability, emissions regulations, and operational efficiency. This article explores key considerations for businesses running medium-capacity steam systems.

LOOKING FOR A RELIABLE COAL SUPPLY PARTNER? We source and deliver high-quality coal grades including peas, small nuts, duff, and RB1 to meet the needs of local and export buyers. Contact us for pricing, specs, or bulk orders

Understanding the Current Role of Coal in Boilers

Coal remains a practical fuel source for medium-sized boiler systems, especially in regions where infrastructure and energy costs make other fuels less viable. Despite growing environmental concerns, its availability and energy density continue to support operations in industrial sectors.

Coal is still widely used in process heating and steam generation in industries like textiles, food processing, and manufacturing.

Medium-sized boilers typically range from 1,000 to 20,000 kg/hr in steam output.

In South Africa, 35% of steam boilers are under 1,000 kg/hr, while only 3% exceed 20,000 kg/hr.

Coal is often preferred in older facilities where equipment was originally designed for solid fuels.

The relative cost per kilowatt-hour from coal can be lower compared to diesel or electricity.

While its role is shrinking globally, coal remains embedded in many industrial operations due to its low upfront fuel cost and legacy system compatibility. Learn more about the difference between peas and small nuts.

Evaluating Efficiency and Fuel Cost Dynamics

When assessing fuel options, operational efficiency and cost are major deciding factors. Coal offers a balance of steady combustion and low cost but comes with trade-offs.

Coal combustion efficiency averages 75% to 85%, lower than natural gas but higher than biomass without pretreatment.

Steam output per ton of coal is predictable and scalable with proper boiler tuning.

On-site coal storage and manual handling increase labor costs and safety requirements.

Price fluctuations are moderate compared to diesel and global LNG markets.

Ongoing emissions penalties and future carbon tax plans could change long-term ROI.

For many medium-sized operations, especially in remote or grid-challenged regions, coal's price stability still offsets its lower combustion efficiency. Learn more on how to boost boiler efficiency with the right coal products.

Comparing Coal with Other Boiler Fuels

Switching fuels isn’t just about cost. Each option has implications for maintenance, emissions, and operational complexity. Here’s how coal stacks up:

Natural gas: Cleaner and more efficient, but limited availability in many parts of South Africa.

Diesel: Easy to handle and store, but volatile pricing and high emissions.

Biomass: Renewable and low-carbon, but inconsistent calorific value and supply logistics.

Electricity: Cleanest and simplest to control, but cost-prohibitive for high-load steam systems.

Coal remains competitive when access to cleaner fuels is limited or when the cost of retrofitting isn’t justifiable.

Environmental Pressures and Compliance Challenges

Environmental regulation is pushing many facilities to reconsider coal usage. However, compliance isn’t always a straightforward shift for medium plants.

Coal combustion is a major source of particulate matter, sulfur dioxide, and nitrogen oxides.

The South African Air Quality Act imposes limits that medium plants may struggle to meet.

Scrubber retrofits or fuel switching can involve downtime and capital investment.

Facilities under 50 MW may fall under softer compliance thresholds, delaying transitions.

Emissions reporting and carbon footprint disclosures are increasingly expected by clients.

While pressure is mounting, many medium-sized operations delay transitions due to limited capital or site-specific infrastructure constraints.

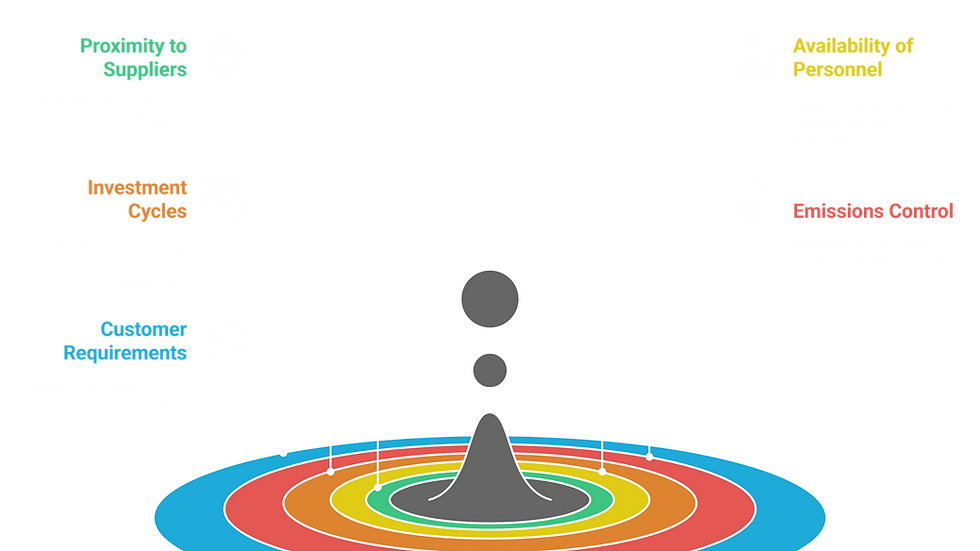

Factors That Influence Fuel Decisions

Choosing to stick with coal or transition to another fuel involves multiple business, technical, and logistical factors.

Proximity to coal suppliers and reliability of transport.

Availability of trained personnel to manage coal boilers.

Investment cycles and remaining useful life of current equipment.

Existing emissions control systems or need for retrofits.

Customer requirements or ESG mandates influencing procurement decisions.

Each factor must be evaluated in the context of long-term growth, market pressures, and plant-specific operating requirements.

Technology Upgrades That Improve Coal Viability

Modernization helps older systems meet environmental standards while improving efficiency and safety. Even coal-based plants can improve performance.

Automated stokers and feeding systems reduce labor and improve combustion consistency.

Oxygen trim and control systems optimize air-fuel ratio for cleaner burns.

Real-time monitoring platforms allow predictive maintenance and lower unplanned downtime.

Bag filters and scrubbers reduce PM and SOx emissions.

Insulation upgrades and heat recovery systems boost energy output per kg of coal.

Investment in these upgrades helps extend the lifespan and compliance viability of existing coal-based boiler plants.

Coal Still Has a Place, With Caveats

Coal continues to serve a functional role in South Africa’s medium boiler operations. With a significant number of units under 1,000 kg/hr and only a small fraction exceeding 20,000 kg/hr, most users operate in a size range where fuel flexibility is limited.

Until gas infrastructure expands or electricity prices stabilize, coal remains a go-to fuel for specific industries. The key is to align its use with emissions mitigation strategies and efficiency improvements that support both regulatory compliance and long-term cost control.

Frequently Asked Questions

What size qualifies as a medium-sized boiler?

A medium-sized steam boiler typically falls between 1,000 kg/hr and 20,000 kg/hr of steam output. In South Africa, this category includes the majority of operational units. Around 35% of boilers in the country fall below 1,000 kg/hr, while only about 3% are larger than 20,000 kg/hr. Medium boilers serve industries like textiles, dairy, and light manufacturing that require steady but moderate steam loads.

Why do companies still use coal for boilers?

Many companies continue using coal because it’s affordable, readily available, and compatible with their existing infrastructure. In regions where gas pipelines are limited or electricity is unreliable or expensive, coal offers a steady, low-cost energy source. Transitioning to other fuels often requires expensive retrofits or system overhauls, which medium-sized operations may find difficult to justify within current budget cycles.

Are coal boilers being phased out in South Africa?

Yes, but gradually. Larger power producers and government facilities are under pressure to decarbonize, but smaller and medium-sized operations often operate under more flexible regulations. The Air Quality Act and carbon-related taxes are pushing the industry toward cleaner alternatives, but the pace of change depends on the site’s location, capacity, and access to other fuel types. Rural or off-grid sites often rely on coal due to limited alternatives.

How does coal compare to biomass for boiler fuel?

Coal provides more consistent energy output and is easier to store in bulk. Biomass, while renewable and lower in carbon emissions, varies in moisture and calorific value, which can affect combustion efficiency. Coal systems are often simpler to operate at scale, while biomass requires careful fuel handling and feeder system upgrades. However, biomass has strong ESG appeal and may be incentivized in future regulations.

What are the risks of continuing to use coal?

Continuing to use coal exposes businesses to rising emissions penalties, reputational risks, and supply disruptions as global markets shift. Insurance companies, investors, and clients increasingly scrutinize carbon-heavy operations. Operationally, coal requires more maintenance and safety controls due to ash, soot, and manual handling. Over time, the cost of staying compliant with emissions laws may outweigh the fuel savings, making cleaner options more attractive for long-term planning.